Wood-Fired Ceramics

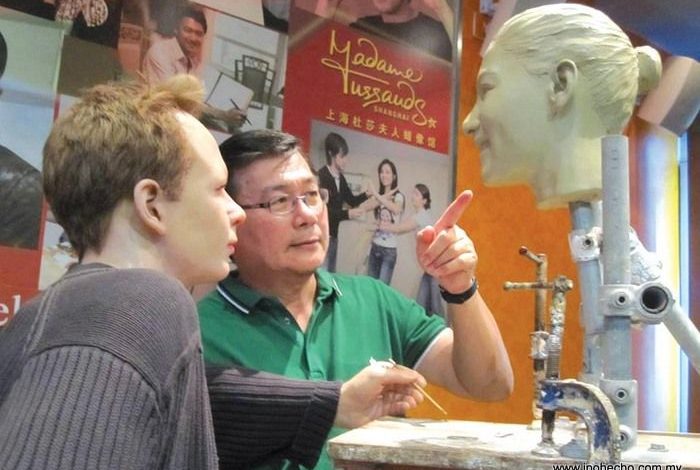

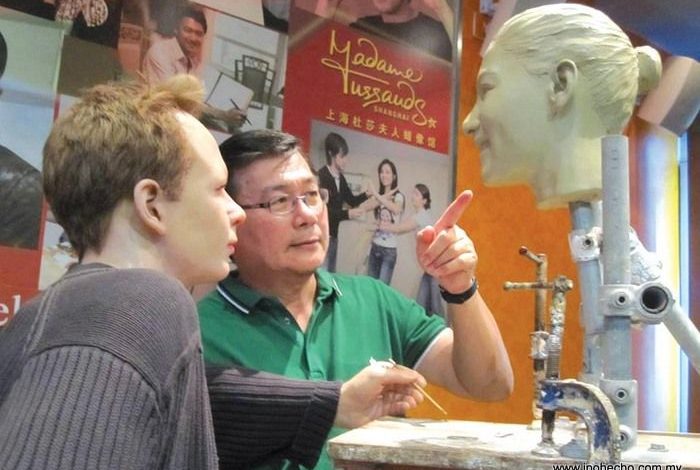

The project, which began with the construction of a cave kiln at the premises of Xin Fa Pottery in Jalan Kuala Kangsar in December 2013, was an effort to preserve the legacy of wood-fired ceramic art. The cave kiln, smaller in size compared to a commercial kiln, and now named Ipohgama (“gama” Japanese for kiln), was made from materials from an abandoned kiln.

With Chin Kam Peng, Xin Fa Pottery partner, as adviser, the construction of the kiln took about eight months to complete. Its first job was to fire 200 ceramic creations for 33 hours at an extremely high temperature of up to 1300 degrees Celsius.

About half of the finished artworks were selected for display at the exhibition, jointly organised by Studio Taojie Fang, Xin Fa Pottery, The Living Art and Culture Creation Art Con. It was launched by Dato’ See Tean Seng, adviser to Ipoh Traditional Cultural Centre.

A photo gallery detailing the history of the project, from construction of the kiln to the production of the first batch of ceramics, was also on display.

“Hopefully, with this exhibition the public will have a better understanding on the process of making wood-fired ceramics and appreciate the beauty of this fine art,” said Tan Voon Yam of Studio Taojie Fang to Ipoh Echo.

Besides preserving this traditional technique of ceramic-making, the collaborative effort helped strengthen the friendship between artisans from Malaysia and Singapore, thus creating a convenient platform for the exchange of ideas and knowledge.

Visitors to the exhibition got first-hand knowledge on ceramic-making, most of whom were exposed to ceramic art for the first time.

For further information on Ipohgama, log on to Facebook at: https://www.facebook.com/groups/657105124380578/

Emily